We manufacture a diverse selection of quality aluminium bronze cast heaters which provide for better results in uniform heat distribution and efficiency. The high thermal conductivity of our aluminium cast bronze heaters allow an extremely uniform temperature to be applied to the component surfaces, alleviating hot or cold spots which may affect the equipment’s performance.

Our cast heaters are provided by a tubular sheathed wire element which has long been recognised for its reliability, strength and adaptability. It is due to the versatility of this element that cast aluminium bronze heaters can be manufactured to suit limitless applications and specifications. All heaters are designed on-site, from tubular heating element design and construction, element forming, foundry casting to machining and electrical connection. With control over the entire process, we guarantee our cast heaters’ performs to the highest standards.

We have vast experience of designing and manufacturing bronze cast heaters combined with an on-going policy of research and development. Our qualified design engineers would welcome the opportunity to discuss and advise you on your requirements and applications for our aluminium bronze cast heaters.

Advantages

High Thermal Conductivity

Providing extremely uniform temperatures over the whole of the heated surfaces.

Accurate Temperature Control

The high thermal conductivity eliminates any hot or cold spots that may occur with other forms of heating. This uniform heat distribution makes for accurate temperature control.

Exceptionally Long Life

Utilising a recognisable reliable tubular sheath wire element and ribbed construction, Cast Heaters provide a good resistance to misuse.

Efficiency

The high thermal conductivity rapidly conducts this heat away from the tubular element to the component surface.

Contamination Resistant

With the heating element cast into the aluminium and together with sealed terminal boxes, the cast heater becomes a contaminant resistant heating unit.

Cast Aluminium Finned

Forced air cooling of extruder barrels using finned heaters has proved itself in the field for many years. Advances in casting methods producing more fin area and with increased output and efficiency of modern blowers enable air cooling to compete with water cooling in many applications. Its advantages are mainly; clean, efficient, relatively inexpensive and easy to maintain.

The finned heaters are cast in halves bolted together and machined in pairs to fit exactly on extruder barrels. They can be supplied with close fitting air cowls to increase efficiency, insulated to reduce heat losses and reduce ambient outer casing temperatures and fitted with inlet and outlet air deflecting boxes with fan mounting attachment plate.

With high output blowers (single or double outlet) bolted to the inlet box, we are able to supply the complete heating and cooling unit.

We also specialise in complete machine conversions from water cooling to air cooling systems.

Cast Aluminium / Bronze Heaters / Coolers

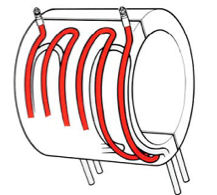

Liquid cooling has been used in plastic extrusion for many years and is generally recognised as one of the most efficient forms available. Aluminium / Bronze heater coolers are now considered standard in the plastics process industry, replacing expensive machine grooved barrels.

The heater coolers are cast in halves, strapped or bolted together and machined in pairs to fit exactly on extruder barrels. They are available with single or double cooling tubes which can be cut to length, pre-formed, to accommodate extruder obstacles or factory fitted with various types of pipe fittings.

Cast in connectors are available as standard as they are easy to connect and help prevent damage during storage and transit. Standard heater and water cooling tube layout The design and layout of the cooling tube are very important as continuous heating and cooling cycles create internal thermal stresses which may cause premature failure to an incorrectly designed cooling tube.

For more information regarding our aluminium bronze cast heaters, email sales@elmatic.co.uk and we will respond to your message as quickly as possible. Furthermore, Elmatic is the leading manufacturers for quality electric and industrial heating elements.

Delivery & Enquiries

Most items are available for delivery in 4/5 or 2/3 working days. However, we do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.

GET IN TOUCH sales@elmatic.co.uk

sales@elmatic.co.uk 029 2077 8727

029 2077 8727 Wentloog Rd, Rumney, Cardiff, CF3 1XH

Wentloog Rd, Rumney, Cardiff, CF3 1XH